If you’re searching for the best explosion-proof fans for paint booths in 2025, I’ve got you covered. I know safety is top priority, so I recommend fans with explosion-proof construction, certified for hazardous environments, and capable of high airflow to keep fumes safe. Models like VEVOR, YITAHOME, and DWVO offer durable, portable, and powerful options that meet industry standards. Keep going, and I’ll guide you through the top choices and key factors for your needs.

Key Takeaways

- Look for fans with explosion-proof certifications like ATEX, IECEx, or UL to ensure safe operation in hazardous environments.

- Prioritize models with high airflow capacity (above 2,000 CFM) for efficient ventilation in paint booths.

- Choose fans constructed with durable, corrosion-resistant materials such as stainless steel or cast iron for longevity.

- Consider portable designs with wheels and handles for flexible positioning and easy maintenance.

- Check noise levels and safety features like sealed wiring and spark prevention to ensure a safe and comfortable working environment.

VEVOR Industrial Portable Ventilator

If you’re looking for a reliable ventilation solution for hazardous environments like paint booths, the VEVOR Industrial Portable Ventilator is an excellent choice. It features a powerful 1.1kW AC motor and an explosion-proof axial blower that delivers 4240 CFM airflow, ensuring efficient removal of fumes, dust, and hot air. Built with sturdy steel and coated for corrosion resistance, it’s designed for durability and long-term use. Its portability is unmatched, with four wheels, two handles, and a 16.4-foot cord. Safety is a top priority, thanks to its IP44 waterproof rating, overheating protection, and ATEX explosion-proof certification, making it ideal for challenging work sites.

Best For: professionals working in hazardous environments such as paint booths, warehouses, workshops, and confined spaces requiring reliable and safe ventilation solutions.

Pros:

- Powerful 1.1kW AC motor delivering 4240 CFM airflow for efficient ventilation.

- Durable construction with corrosion-resistant steel and ETL certification ensures long-term reliability.

- Equipped with safety features including IP44 waterproof rating, overheating protection, and ATEX explosion-proof certification.

Cons:

- No plug included with the 16.4-foot power cord, requiring an additional purchase or setup.

- Heavy and large dimensions may limit portability in tight spaces.

- May require maintenance of safety features to ensure ongoing compliance and performance.

YITAHOME Explosion Proof Exhaust Fan 10 Inch

The YITAHOME Explosion Proof Exhaust Fan 10 Inch stands out as an essential choice for those working in hazardous environments where reliable ventilation is critical. Its explosion-proof construction, including specialized wiring and motors, ensures safe operation in risky settings. The fan features durable aluminum blades, a painted finish, and an adjustable A-frame for flexible airflow direction. With an airflow capacity of 1,942 CFM, it effectively ventilates large spaces like paint booths and warehouses. Weighing around 34 pounds, it’s portable and easy to position. The included 16-foot PVC duct and remote control make setup and operation straightforward, making it a versatile, safety-focused ventilation solution.

Best For: industrial workers and professionals operating in hazardous environments requiring reliable, explosion-proof ventilation solutions.

Pros:

- Explosion-proof design ensures safe operation in hazardous settings.

- High airflow capacity of 1,942 CFM effectively ventilates large spaces.

- Portable and versatile with adjustable A-frame and included duct hose, facilitating easy positioning and use.

Cons:

- Relatively heavy at approximately 34 pounds, which may require additional effort to move.

- Limited to indoor use, restricting outdoor applications.

- No battery operation; reliant on a 110V electrical outlet, reducing mobility in some locations.

YITAHOME 12-Inch Explosion Proof Fan

The YITAHOME 12-Inch Explosion Proof Fan stands out as a top choice for anyone needing reliable ventilation in hazardous environments, thanks to its explosion-proof motor and specialized construction. Its design incorporates safety features like durable materials, wiring, and construction techniques that ensure safe operation in paint booths, industrial settings, and chemical facilities. The adjustable A-frame and flexible PVC duct hose make positioning easy, while its powerful airflow suits demanding applications. With a 16-foot duct and straightforward setup, it’s versatile for various environments such as warehouses, shipyards, and workshops. This fan combines safety, flexibility, and performance, making it an excellent investment for industrial ventilation needs.

Best For: industrial and hazardous environment professionals requiring safe, reliable ventilation solutions such as paint booths, factories, and chemical facilities.

Pros:

- Explosion-proof motor ensures safe operation in hazardous environments

- Adjustable A-frame and flexible PVC duct allow customizable airflow and positioning

- Powerful airflow suitable for demanding industrial applications

Cons:

- May be heavier and bulkier due to robust construction and explosion-proof features

- Setup and transportation require careful handling because of its size and safety components

- Higher cost compared to standard fans due to specialized safety features

DWVO 12 Inch Explosion Proof Fan with Flexible Duct

Designed for hazardous environments, the DWVO 12 Inch Explosion Proof Fan with Flexible Duct offers a reliable ventilation solution for paint booths and other flammable settings. Its explosion-proof motors and specialized wiring guarantee safety during demanding operations. The adjustable angle with a detachable A-frame lets me direct airflow precisely where needed, while the 16-foot flexible PVC duct provides wide coverage and easy setup. With a high airflow capacity of 2719 CFM and a compact, portable design, it handles tough industrial ventilation tasks effectively. Weighing around 37 pounds, it’s built for indoor use in garages, factories, and warehouses, making it a versatile choice for demanding environments.

Best For: industrial facilities, hazardous environments, and professionals needing safe and reliable ventilation in flammable or enclosed spaces.

Pros:

- Explosion-proof motors and specialized wiring ensure safety in hazardous settings

- Adjustable airflow direction with detachable A-frame for precise ventilation control

- Includes a 16-foot flexible PVC duct for wide coverage and easy setup

Cons:

- Customer reviews indicate it can be noisier and less powerful than older models

- Some users perceive the airflow as weaker, questioning its efficiency for demanding tasks

- Limited to indoor use with a weight of approximately 37 pounds, which may affect portability for some users

Vevor Explosion Proof Fan, 12 Inch (300mm) Utility Blower

If you’re working in hazardous environments where explosion-proof equipment is essential, the Vevor Explosion Proof Fan, 12 Inch (300mm) Utility Blower, stands out as a reliable choice. It features an explosion-proof switch that enhances safety, ensuring dependable operation in explosive conditions. Its 550W motor delivers 3450 RPM, providing powerful airflow for effective ventilation. Built with industrial-grade materials, this heavy-duty, compact axial flow fan is designed for demanding industrial and construction applications. Operating at 110V 60Hz, it offers consistent, reliable performance, making it ideal for extraction and ventilation in hazardous settings like paint booths and workshops.

Best For: professionals working in hazardous industrial or construction environments requiring explosion-proof ventilation solutions.

Pros:

- Equipped with an explosion-proof switch for enhanced safety in explosive conditions

- Powerful 550W motor delivers high airflow at 3450 RPM for efficient ventilation

- Heavy-duty, compact design suitable for demanding industrial applications

Cons:

- Operating at 110V may limit use in regions with different voltage standards

- Heavier and bulkier compared to smaller fans, potentially affecting portability

- May require specialized maintenance or handling due to industrial-grade construction

16 Axial Fan Cylinder Pipe Explosion-proof Spray Booth Paint Fumes Exhaust Fan

When working in environments with paint fumes and flammable vapors, safety is paramount, making explosion-proof fans essential. The Axial Fan Cylinder Pipe Explosion-proof Spray Booth Paint Fumes Exhaust Fan offers reliable ventilation with a durable copper motor and high-quality materials like stainless steel blades and a carbon steel shell. Its cylindrical design and powerful airflow—up to 5400 m³/h—ensure effective fume extraction. Despite some noise and packaging concerns, users appreciate its stable operation, low power consumption, and versatility across industrial settings. This fan is a solid choice for maintaining a safe, efficient workspace in paint booths and other hazardous environments.

Best For: professionals and industrial facilities needing explosion-proof ventilation in paint booths, workshops, warehouses, and other hazardous environments.

Pros:

- High airflow capacity up to 5400 m³/h for effective fume extraction

- Durable construction with copper motor and stainless steel blades for long-lasting use

- Stable operation with vibration reduction features and low power consumption

Cons:

- Some users report the fan operates quite loudly at around 87 dB

- Frame and packaging may feel flimsy or less sturdy than expected

- No remote control and single-speed design may limit user convenience

iLiving Explosion Proof Utility High Velocity Blower

The iLiving Explosion Proof Utility High Velocity Blower is an excellent choice for industrial environments where safety and power are paramount. It features a durable 12-inch aluminum blade and a 550W copper motor, delivering an impressive 2720 CFM airflow at 3300 RPM. Its explosion-proof design makes it ideal for hazardous areas with fumes or gases, while its rugged steel frame guarantees long-lasting use. Weighing just 32 pounds, it’s portable yet sturdy, perfect for venting paint fumes, hot air, or gases in warehouses, workshops, and garages. With CE certification and thermal protection, it combines safety, efficiency, and reliability in a compact, high-performance package.

Best For: industrial professionals and safety-conscious users needing reliable explosion-proof ventilation in hazardous environments such as warehouses, paint booths, and workshops.

Pros:

- High airflow capacity of 2720 CFM for effective ventilation and exhaust

- Explosion-proof design suitable for hazardous fumes, gases, and dust

- Durable steel frame and rugged construction for long-term heavy-duty use

Cons:

- Relatively high noise level of 69 dB during operation

- Limited to one speed setting, reducing control over airflow intensity

- Packaging may lack padding, increasing risk of shipping dents or missing parts

10 Inch Explosion Proof Fan for Industrial Ventilation

A 10-inch explosion-proof fan like the FICBXRA model is ideal for industrial ventilation needs in hazardous environments. It features a powerful 350W motor spinning at 3300 RPM, delivering 1840 CFM for effective exhaust and air circulation. Its durable steel housing guarantees long-lasting performance, while its lightweight design (just under 40 pounds) makes it portable and easy to move. Built with specialized wiring and explosion-proof components, it’s safe for use in spray booths, warehouses, and workshops. Its high-density covers prevent debris entry, enhancing safety and reliability. Overall, this fan combines robust construction with efficient airflow, making it a top choice for demanding industrial settings.

Best For: industrial facilities, workshops, warehouses, and spray booths requiring safe, high-capacity ventilation in hazardous environments.

Pros:

- Powerful airflow with 1840 CFM at 3300 RPM for efficient ventilation

- Explosion-proof design ensures safety in hazardous settings

- Durable construction with steel housing and high-quality components for longevity

Cons:

- Slightly heavy at nearly 40 pounds, which may affect portability for some users

- Requires a corded electric power source, limiting mobility without extension cords

- Higher cost compared to non-explosion-proof fans, reflecting specialized safety features

16 Inch Explosion Proof Fan with 750W Power

If you’re seeking a reliable explosion-proof fan for paint booths or industrial spaces, the 16-inch model with a powerful 750W motor is an excellent choice. Its high-quality iron and copper construction with a baking paint finish guarantees durability, resisting deformation and wear over time. Operating at 2800 RPM, it delivers an impressive airflow of 8,000 ft³/h, providing efficient ventilation. Safety is a top priority, with a thickened mesh cover secured by four screws to prevent fragments from reaching the blades. Easy to install with pre-drilled holes, this sleek black fan combines robust performance with a modern look, perfect for demanding industrial environments.

Best For: industrial facilities, paint booths, and commercial spaces requiring reliable explosion-proof ventilation.

Pros:

- Durable construction with iron and copper materials and baking paint finish for long-lasting performance.

- Powerful 750W motor operating at 2800 RPM with an airflow of 8,000 ft³/h for efficient ventilation.

- Safe design featuring a thickened mesh cover secured by four screws to prevent fragment hazards.

Cons:

- Installation requires screws (not included), which may be an extra step for some users.

- The fan’s size and power might be excessive for small or residential applications.

- Limited color options, primarily available in sleek black, which may not match all decor styles.

12 Inch Explosion-Proof Fan for Industrial Ventilation

For those managing industrial environments where safety and reliable ventilation are critical, the 12-inch explosion-proof fan stands out as an ideal solution. The REBaiYU FD-300 model features a durable metal body, plastic blades, and a steel safety guard, ensuring safety during operation. It’s portable, wall-mounted, and suitable for indoor use in factories, warehouses, and workshops. Powered by a 125W explosion-proof motor, it delivers an airflow of 2000 m³/h at 2800 RPM, with low noise and app control for ease of use. Despite some skepticism about its certification, this fan offers a practical, efficient option for heat dissipation and fume extraction in hazardous environments.

Best For: industrial facility managers and safety-conscious workers seeking a reliable, portable fan for hazardous environments requiring effective ventilation and heat dissipation.

Pros:

- Durable metal construction with safety features like a steel wire grill for blade protection

- Powerful 125W explosion-proof motor delivering high airflow at 2000 m³/h

- Easy to install and operate via app control, suitable for indoor industrial settings

Cons:

- Questions regarding true explosion-proof certification and verification of safety claims

- Airflow performance may be lower than rated, especially in large or complex spaces

- Limited to a single power level with no cordless option, restricting flexibility in some scenarios

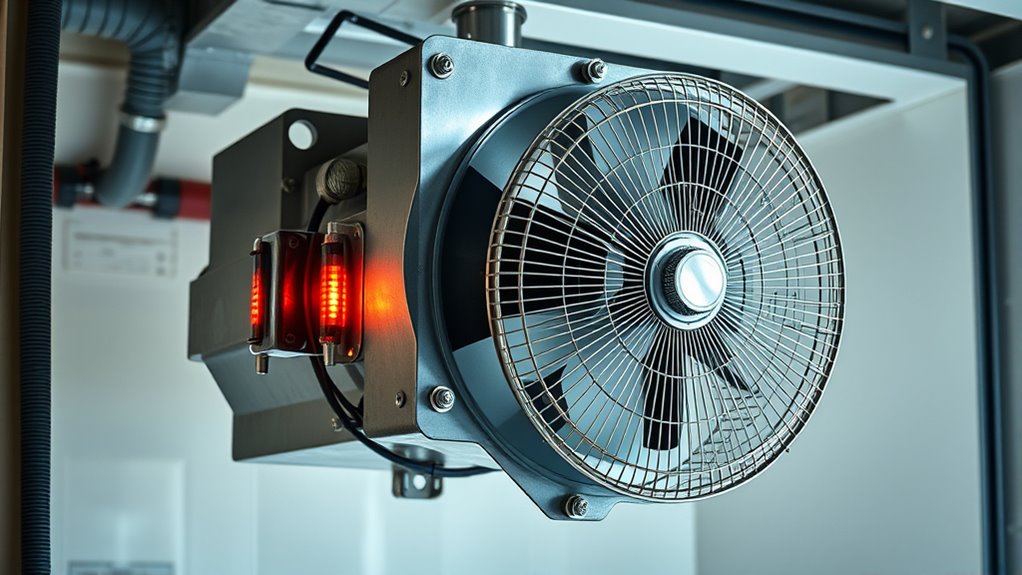

Explosion Proof Fan, Grey and Red Axial Ventilation Fan

The grey and red axial ventilation fan stands out as an ideal choice for industrial settings where safety and durability are paramount, especially in environments with explosive gases or steam, such as paint booths. Its robust construction features corrosion-resistant iron and aluminum components, with an electrostatic spray finish for added protection. Powered by a pure copper motor, it delivers stable, efficient airflow—up to 2880m³/h—while maintaining low noise levels. Certified explosion-proof (Exdll BT4Gb), it ensures safe operation in hazardous atmospheres. Its all-metal housing, protective mesh, and sturdy design make it reliable for long-term use in demanding environments.

Best For: Industrial facilities, warehouses, laboratories, and any environment containing explosive gases or steam requiring reliable, explosion-proof ventilation solutions.

Pros:

- Certified explosion-proof (Exdll BT4Gb) ensuring safety in hazardous environments

- Durable construction with corrosion-resistant iron and aluminum components

- Efficient operation with a pure copper motor and high airflow capacity of 2880m³/h

Cons:

- Relatively heavy at 15kg, which may require sturdy mounting support

- Noise level of 65dB might be noticeable in quieter settings

- Wall-mounted installation may limit flexibility in placement

AW Dual Fans Portable Airbrush Spray Booth Kit with LED Lights and Exhaust Filter Hose

Designed for hobbyists and professionals alike, the AW Dual Fans Portable Airbrush Spray Booth Kit offers powerful ventilation with dual fans that deliver up to 9 m/s wind speed and an airflow of 8 m³/min. It measures 22x19x14 inches, providing a spacious workspace with built-in LED lights for maximum visibility. The kit includes a retractable exhaust hose to vent harmful fumes outdoors, plus two filters to trap paint particles and prevent clogging. Its foldable design with a handle makes it portable and easy to store. The 360-degree rotatable turntable ensures even coverage, and safety is guaranteed with CE and UL certifications.

Best For: hobbyists and professionals seeking a spacious, portable spray booth with powerful ventilation, adjustable lighting, and safety features for detailed painting and decorating projects.

Pros:

- Dual fans with high wind speed and airflow ensure efficient ventilation and quick drying.

- Foldable design with handle allows for easy transport and space-saving storage.

- Adjustable LED lighting provides optimal illumination for precise work.

Cons:

- Size may be too large for compact workspaces or limited areas.

- May require additional setup time for assembly and connection of filters and hoses.

- The noise from dual fans could be disruptive in quiet environments.

Explosion Proof Fan, 16-Inch Axial Flow Blower Fan

If you need reliable, high-capacity ventilation in hazardous environments like paint booths or construction sites, the 16-inch axial flow blower fan stands out as an excellent choice. It features a powerful 370W pure copper motor that delivers airflow up to 5400m³/H, high air pressure, and speeds of 1420rpm. Its corrosion-resistant housing and stainless steel blades ensure durability, while the triangular fixation reduces vibration and noise. Easy to install on walls or ducts, it offers stable, long-lasting performance with minimal noise at 71dB. This fan is ideal for air exchange, dust removal, temperature control, and even special effects.

Best For: industrial facilities, construction sites, and paint booths requiring durable, high-capacity ventilation in hazardous environments.

Pros:

- Powerful airflow capacity up to 5400m³/H for efficient ventilation needs

- Durable construction with corrosion-resistant housing and stainless steel blades

- Quiet operation at 71dB with vibration-reducing triangular fixation

Cons:

- Actual dimensions may differ from advertised size, requiring modifications for installation

- Lacks wiring diagram and detailed installation instructions in the package

- Customer reviews indicate discrepancies in product dimensions and assembly requirements

TBVECHI Explosion-Proof Axial Fan (16″) 1.5HP Ventilation Blower

For those seeking a robust ventilation solution in hazardous environments, the TBVECHI Explosion-Proof Axial Fan (16″) 1.5HP Ventilation Blower stands out with its explosion-proof design and high airflow capacity. Made from durable carbon steel with stainless steel blades, it’s built to withstand heat and corrosion. Its compact, cylindrical shape allows flexible installation, whether wall-mounted or ducted. Powered by a reliable 370W copper motor, it delivers up to 5400 m³/h airflow at low noise levels. Safety features include protective covers and ATEX certification, ensuring safe operation. This fan is ideal for factories, labs, and workshops where safety and performance are critical.

Best For: industrial facilities, laboratories, and workshops requiring safe, reliable, and high-capacity ventilation in hazardous environments.

Pros:

- Explosion-proof design with ATEX certification ensures safe operation in dangerous areas.

- High airflow capacity up to 5400 m³/h with low noise levels for efficient ventilation.

- Durable construction with carbon steel housing and stainless steel blades for corrosion and heat resistance.

Cons:

- Heavy weight may make installation and handling more challenging.

- Packaging issues reported, including occasional dents during shipping.

- Lack of detailed wiring instructions can complicate setup for some users.

Factors to Consider When Choosing an Explosion Proof Fan for Paint Booth

When selecting an explosion-proof fan for a paint booth, I consider key factors like safety certifications and airflow capacity to guarantee reliable operation. I also look at the fan’s explosion-proof features, material durability, and whether its size and portability fit the workspace. These points help me choose a fan that’s safe, efficient, and suitable for my needs.

Safety Certifications Needed

Choosing an explosion-proof fan for a paint booth requires careful attention to safety certifications that verify the product’s compliance with hazardous environment standards. Certifications like ATEX, IECEx, or UL listed confirm the fan meets strict safety requirements, ensuring it won’t ignite flammable atmospheres. These labels indicate the fan has been tested for flame resistance, spark prevention, and secure electrical insulation suitable for explosive zones. It’s essential to verify that the certification covers the specific environment and gases present, such as T1 to T4 classifications for temperature and gas type. Always check that certifications are current and verified by recognized safety organizations. This ensures ongoing compliance and safety, giving you peace of mind that your paint booth operates within the highest safety standards.

Airflow Capacity Requirements

Ensuring the right airflow capacity is essential for effective ventilation and safety in your paint booth. You need to match the fan’s airflow to the booth’s volume, typically aiming for 6-10 air changes per hour. To do this, calculate the required cubic feet per minute (CFM) based on your booth’s size. The fan’s airflow rating should align with your specific needs, whether it’s fume extraction, dust removal, or temperature control. Remember to contemplate the pressure requirements of ducting and filters to maintain consistent airflow. Keep in mind that higher airflow capacities can increase noise and energy use. Balancing these factors ensures your ventilation system operates efficiently, keeps fumes at bay, and maintains a safe working environment.

Explosion-Proof Features

Selecting an explosion-proof fan requires careful attention to its safety features, as these components are designed to prevent sparks and static discharge that could ignite flammable fumes or dust. I look for fans with specialized materials and wiring that minimize the risk of sparks. Explosion-proof motors rated with safety certifications like ATEX are essential for safe operation in hazardous environments. The fan housing should be made from durable, corrosion-resistant metals such as steel or iron, ensuring longevity and safety. Additional features like protective mesh covers, secure mounting, and sealed electrical components help contain sparks and prevent ignition sources. Certified testing confirms the fan’s ability to operate reliably in explosive atmospheres, giving me confidence in its safety and compliance standards.

Material Durability Factors

When evaluating explosion-proof fans for paint booths, the durability of the materials used is essential because these fans operate in harsh, corrosive environments. High-quality materials like carbon steel, stainless steel, or cast iron are crucial for withstanding exposure to chemicals, heat, and moisture. The blades and housing must resist corrosion, wear, and deformation over time to maintain performance. Components such as explosion-proof motors and protective meshes are typically made from corrosion-resistant metals, ensuring safety and longevity in explosive atmospheres. Applying baked paint finishes and electrostatic spraying further enhances resistance to rust, chemicals, and temperature changes. Choosing fans built from robust, high-grade materials means fewer replacements and repairs, providing consistent performance even under demanding conditions.

Size and Portability

The size and portability of explosion-proof fans play a significant role in how well they fit into your paint booth setup. The fan’s diameter and height directly affect airflow capacity and whether it suits your booth’s dimensions. Smaller, lightweight fans are easier to move and reposition, especially in confined or multi-location workspaces, thanks to features like built-in handles or wheels. Larger fans with higher airflow ratings are less portable but essential for ventilating bigger booths or industrial environments. Mounting options such as wall mounting or duct installation also influence space requirements and flexibility. Ultimately, choosing the right size and portability guarantees efficient ventilation without sacrificing ease of use, making your workspace safer and more adaptable.

Power Supply Compatibility

Ensuring your explosion-proof fan is compatible with your power supply is essential for safe and reliable operation. I always check that the fan’s voltage and plug type match my facility’s power source to prevent electrical hazards. It’s also important to verify the fan operates at the correct frequency—whether 50Hz or 60Hz—matching the local power grid. I make sure the fan’s wattage doesn’t exceed my circuit’s capacity, avoiding overloads that could cause failures or fires. Additionally, I confirm that the wiring standards and certifications comply with local safety regulations for hazardous environments. Finally, I consider the power cord length and connector type to ensure safe, convenient connections without strain or risk. Proper compatibility keeps my paint booth running safely and efficiently.

Noise Level Considerations

Have you ever considered how much noise a fan produces in your paint booth? Noise levels for explosion-proof fans typically range from 65 dB to 87 dB. Quieter models are better if you need a low-noise environment, but higher airflow capacities often mean increased noise. Fans exceeding 70 dB can cause discomfort or safety issues during long shifts. To address this, look for fans with noise reduction features like vibration dampening mounts, sound-insulating housings, or noise-absorbing materials. It’s also vital to measure the fan’s decibel output in actual working conditions to guarantee it meets your environment’s standards. Balancing ventilation needs with acceptable noise levels is key to maintaining a safe, comfortable workspace without sacrificing performance.

Installation and Maintenance

Choosing an explosion-proof fan for your paint booth requires careful attention to installation and maintenance factors that guarantee safety and reliability. I recommend selecting a fan designed for easy installation, with features like pre-drilled holes and clear instructions to guarantee secure setup. Regular inspections are crucial—check protective covers, wiring, and motor components for signs of wear, corrosion, or damage. Routine maintenance should include cleaning blades and filters, monitoring for unusual noises or vibrations, and verifying electrical connections to prevent malfunctions. Always follow safety procedures during maintenance, such as disconnecting power and wearing protective gear, to avoid accidents in hazardous environments. Adhering to the manufacturer’s recommended maintenance schedule helps preserve explosion-proof certifications and ensure your fan operates reliably over the long term.

Frequently Asked Questions

What Certifications Are Required for Explosion-Proof Fans in Paint Booths?

I know that explosion-proof fans in paint booths need to have specific certifications to guarantee safety and compliance. Typically, they must be UL or ETL listed, meeting NFPA standards for explosive atmospheres. Additionally, they should have ATEX or IECEx certification if used internationally. These certifications confirm the fan’s design reduces ignition risks and is built to withstand hazardous environments, giving you peace of mind while maintaining safety standards.

How Does Fan Maintenance Impact Safety and Performance?

Did you know that poor fan maintenance can increase safety risks by 30%? I believe regular upkeep is essential because it keeps explosion-proof fans functioning safely and efficiently. When I maintain my fans properly, I notice better airflow, reduced fire hazards, and consistent performance. Skipping maintenance can lead to dust buildup and motor wear, which compromise safety and cause costly breakdowns. Staying diligent ensures my paint booth remains safe and high-performing.

Can Explosion-Proof Fans Operate in Various Hazardous Environments?

Yes, explosion-proof fans can operate in various hazardous environments. I’ve seen them excel in settings like paint booths, chemical plants, and grain silos. Their design guarantees they won’t trigger sparks or explosions, making them incredibly versatile. When choosing one, I always look for certifications and proper installation to guarantee safety and peak performance. They’re reliable tools for maintaining safety standards across different dangerous environments.

What Is the Typical Lifespan of Explosion-Proof Fans in Industrial Settings?

Explosion-proof fans typically last between 10 to 15 years in industrial settings, depending on usage and maintenance. I’ve found that regular inspections, proper cleaning, and timely repairs can considerably extend their lifespan. It’s important to choose high-quality fans and follow manufacturer guidelines to ensure safety and performance over the years. Proper care not only prolongs their life but also maintains a safe environment in hazardous areas.

Are There Energy-Efficient Explosion-Proof Fan Options Available?

Absolutely, there are energy-efficient explosion-proof fans available. For instance, I recently helped a client upgrade their paint booth ventilation with a model featuring variable speed drives and high-efficiency motors. This setup reduced energy consumption by 30% while maintaining safety standards. These fans use advanced motor technology and smart controls, making them a smart choice for eco-conscious facilities that want to save on energy costs without compromising performance.

Conclusion

Choosing the right explosion-proof fan is like selecting a trusted guardian for your paint booth—it’s not just about safety, but peace of mind. As you weigh your options, remember that performance and protection go hand in hand, guiding your work with confidence. In this journey, the right fan isn’t just equipment; it’s the silent promise that every spray is a step toward safety and success. Trust your choice, and let safety lead the way.