I’ve researched the top pressure pot systems for a flawless finish in 2025, including models from TCP Global, Vevor, Astro Pneumatic, Barton, and Fuji. These systems offer durable construction, precise pressure control, and compatibility with various coatings. Whether you need a small, portable unit or a large-capacity pressure cooker, there’s a suitable option for every project. Keep exploring to find details on their features and how to choose the best one for your needs.

Key Takeaways

- Prioritize systems with precise pressure regulation and high-quality gauges for consistent, flawless finishes.

- Choose durable materials like stainless steel or coated steel to support chemical resistance and long-term reliability.

- Select appropriately sized pressure pots (e.g., 10-liter or larger) suited for professional or detailed applications.

- Ensure compatibility with high-precision spray guns featuring adjustable nozzles for fine atomization.

- Consider safety features like relief valves, locking lids, and automatic shut-offs to prevent overpressure issues.

TCP Global Heavy Duty Steel Pressure Pot for Casting and Painting

If you’re looking for a reliable all-in-one solution for medium-volume painting or casting projects, the TCP Global Heavy Duty Steel Pressure Pot is an excellent choice. It includes a 2-quart steel pressure pot, screw-on lid with gasket, regulator, pressure gauge, spray gun with a 1.5mm fluid tip, and 5-foot hoses—making setup straightforward. The heavy-duty spray gun offers precision and efficiency, perfect for automotive, latex, varnishes, and more. With a tight seal and recommended pressure of 30-45 psi, it guarantees consistent performance. Built for durability, this system handles demanding environments, delivering professional results in various coating applications.

Best For: DIY enthusiasts and professionals seeking a durable, all-in-one medium-volume painting or casting system for automotive, woodworking, or general coating projects.

Pros:

- Complete kit with pressure pot, hoses, regulator, and spray gun for easy setup

- Heavy-duty steel construction ensures durability and long-lasting performance

- Versatile application for various coatings including automotive paints, varnishes, and primers

Cons:

- Suitable primarily for medium-volume projects; may not be ideal for large-scale industrial use

- Requires a compressor capable of maintaining 30-45 psi for optimal operation

- Slightly heavier due to steel construction, which may affect portability

TCP Global Heavy Duty Steel Pressure Pot Paint Tank (10 Liter)

The TCP Global Heavy Duty Steel Pressure Pot Paint Tank (10 Liter) stands out for its durable construction and reliable performance, making it an excellent choice for professionals and serious hobbyists tackling large-scale painting and casting projects. Its steel body with a clamp-on lid and gasket guarantees a leak-proof seal, while the 10-liter capacity handles substantial material volumes. Equipped with a fluid pressure regulator and gauge, it maintains consistent pressure of 25-30 psi, with a maximum of 50 psi. Compatible with standard equipment, it handles various materials like paints, primers, and adhesives, delivering commercial-quality finishes with efficiency and precision.

Best For: professionals and serious hobbyists seeking a durable, high-capacity pressure pot for large-scale painting, casting, and finishing projects.

Pros:

- Heavy-duty steel construction ensures durability and long-lasting performance

- Precise pressure regulation for consistent material application

- Compatible with a wide range of paints and adhesives for versatile use

Cons:

- Slightly heavier and bulkier than smaller, less robust models

- Requires a compressor with appropriate pressure capacity for optimal operation

- May be overkill for small or occasional projects

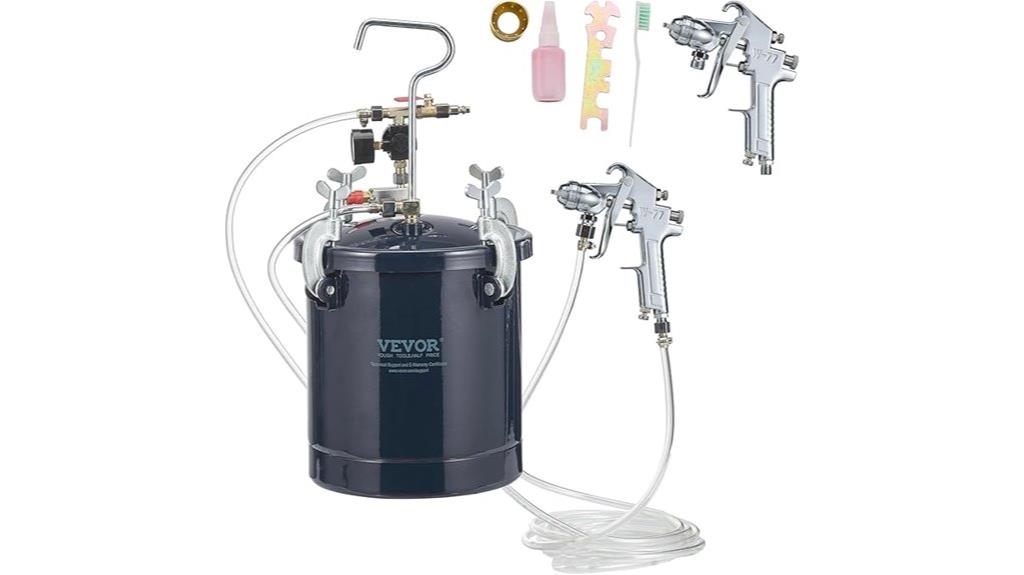

Vevor Spray Paint Pressure Pot Tank, 10L/2.5gal Air Paint Pressure Pot

For those seeking an efficient and versatile pressure pot system, the Vevor Spray Paint Pressure Pot Tank stands out with its generous 10-liter capacity and included dual spray guns. It features 1/4 inlet and outlet ports and a 3/8 fluid outlet, ensuring smooth spray gun connections. Compatible with various paints like latex and metallic, it works best with spray guns that have 4mm+ nozzles. The system includes adjustable nozzles, air, and paint flow controls, plus a pressure gauge and safety valve for secure operation. Constructed from high-quality, pressure-resistant materials, it’s perfect for both industrial and home projects, offering reliable, high-quality finishes.

Best For: DIY enthusiasts, professional painters, and automotive, architectural, or craft workers seeking a reliable, versatile spray paint system for high-quality finishes.

Pros:

- Large 10L capacity with efficient connection ports suitable for various paint types.

- Comes with two different nozzles and adjustable controls for precise spray patterns and particle sizes.

- Constructed with durable, pressure-resistant materials and equipped with safety features like a pressure gauge and automatic release valve.

Cons:

- Requires a compatible spray gun with a 4mm+ nozzle for latex paints, which may entail additional purchases.

- Heavier and bulkier due to its metal construction, potentially less portable for frequent moving.

- May need some assembly or adjustment for optimal operation, especially for beginners.

T-fal Clipso Stainless Steel Pressure Cooker 8 Quart

With its durable stainless steel construction and even heat distribution, the T-fal Clipso 8 Quart Pressure Cooker is an excellent choice for home cooks seeking reliable performance and versatile cooking options. Its encapsulated base works with all cooktops, including induction, ensuring fast, efficient heating. The cooker’s safety features, like secure locking, pressure indicators, and a variable steam release valve, provide peace of mind. With a generous 8-quart capacity, it’s perfect for large meals and batch cooking. Easy to clean, dishwasher safe, and equipped with useful accessories like a steam basket, it delivers consistent results for everything from tender meats to soups and desserts.

Best For: Home cooks looking for a durable, versatile pressure cooker that can handle large batches and diverse recipes with safety and efficiency.

Pros:

- Made from premium stainless steel for durability and long-lasting performance

- Compatible with all cooktops, including induction, for versatile use

- Equipped with safety features like locking mechanisms, pressure indicators, and a steam release valve

Cons:

- Heavier weight of 10 pounds may require effort to handle

- Slightly larger size may not be suitable for small kitchens or limited storage space

- Requires initial water test and familiarity with pressure indicators for safe operation

Astro Pneumatic 2 Quart Pressure Pot with Gun and Hose

If you’re tackling large surface areas like buses or trucks and need precise control, the Astro Pneumatic 2 Quart Pressure Pot with Gun and Hose stands out as an excellent choice. Its 2-quart metal tank and adjustable spray gun make it perfect for applying primers, lacquers, or water-based paints smoothly. The system includes twin 6-foot hoses, a pressure gauge, and a regulator for consistent spray patterns. Weighing just 4.4 pounds, it’s lightweight yet durable, ideal for both DIYers and professionals. While some users report hose issues or handling challenges, proper maintenance and adjustments guarantee flawless finishes on big projects.

Best For: DIYers and professionals tackling large surface projects like buses, trucks, and vans who need precise control and efficient spray application.

Pros:

- Includes a durable 2-quart metal pressure tank with adjustable spray gun for versatile use.

- Comes with twin 6-foot hoses, pressure gauge, and regulator for consistent and controlled spraying.

- Lightweight at 4.4 pounds, making it easier to maneuver during large or extended projects.

Cons:

- Some users experience hose blowouts or leaks, requiring maintenance or replacement.

- Handling can be awkward for mobile use or in tight spaces due to weight and size.

- Potential for cracks or damage to the pressure pot threads, which may affect sealing and longevity.

All American 1930-21.5qt Pressure Cooker/Canner

The All American 1930-21.5qt Pressure Cooker/Canner stands out as the top choice for home canners who prioritize safety and durability. It’s designed to meet USDA standards, making it perfect for safely preserving meats, vegetables, and fruits. Its metal-to-metal sealing system eliminates gaskets, reducing maintenance and ensuring a steam-tight seal. The easy-to-read steam gauge and precise regulator weight give me confidence in pressure control. Built with high-quality materials and reinforced edges, it’s made to last for generations. Whether I’m using gas, electric, or flat-top stoves, this American-made pressure cooker provides reliable, long-lasting performance with safety at the forefront.

Best For: home canners seeking a durable, safe, and high-capacity pressure cooker for preserving meats, vegetables, and fruits with long-lasting performance.

Pros:

- Metal-to-metal sealing system eliminates gasket replacements, reducing maintenance costs.

- Easy-to-read steam gauge and precise regulator weight enhance pressure control accuracy.

- Constructed with high-quality materials and reinforced edges for exceptional durability and longevity.

Cons:

- Heavier and bulkier design may be less convenient for storage or handling.

- Requires familiarity with pressure canning procedures to ensure safety and proper use.

- May have a higher initial cost compared to smaller or less robust models.

Blulu 10L Pressure Pot Paint Tank with Regulator & Gauge

The Blulu 10L Pressure Pot Paint Tank stands out for its heavy-duty steel construction and precise pressure control, making it an excellent choice for professionals who demand reliable and high-quality results. Its 10-liter capacity is perfect for resin casting, spray painting, and auto body work, offering durability and consistency. Equipped with a fluid pressure regulator, pressure gauge, and safety features like a relief valve and clamp-on lid, it guarantees safe operation at 25-30 PSI. The tank’s stable design, with rubber feet and compatible ports, minimizes movement during use, making it ideal for large-scale projects requiring uniform coating and flawless finishes.

Best For: Professional auto body shops, resin casters, and large-scale painters seeking a reliable, durable pressure pot for high-volume coating applications.

Pros:

- Heavy-duty steel construction ensures durability and long-term use

- Precise pressure regulation with gauge and relief valve for safety and consistency

- Versatile compatibility with various coatings including automotive paints, varnishes, and adhesives

Cons:

- Heavier weight may require additional effort for transportation and setup

- Limited to 10-liter capacity, which may not suit very large or continuous production needs

- Requires regular maintenance to ensure seal integrity and safety features remain effective

California Air Tools 1810C Pressure Pot for Epoxy Resin Casting

Designed specifically for epoxy resin casting, the California Air Tools 1810C Pressure Pot stands out thanks to its durable coated steel tank, which makes cleanup straightforward and supports consistent performance. Its compact size, with internal dimensions of 17 3/4″ W x 9 5/8″ D and external dimensions of 19.5″ W x 22.5″ H, makes it easy to handle and position. Weighing 64 pounds, it offers a 10-gallon capacity, perfect for various projects. Equipped with rubber feet for stability and castor wheels for mobility, it’s versatile for different workspace setups. The pressure system reaches up to 80 PSI, with precise control via regulator, ball valve, and relief valve, ensuring safe operation.

Best For: hobbyists, artisans, and professionals seeking a reliable, portable pressure pot for epoxy resin casting projects.

Pros:

- Durable coated steel tank facilitates easy cleanup and long-term use

- Compact size with mobility features like castor wheels and rubber feet for flexible workspace setup

- Precise pressure control with regulator, ball valve, and relief valve ensures safe and efficient operation

Cons:

- Weighs 64 pounds, which may be heavy for some users to lift or reposition frequently

- Limited to 10-gallon capacity, which might be insufficient for large-scale or high-volume projects

- Maximum pressure of 80 PSI may restrict certain casting applications requiring higher pressure

Astro 2PG8S 2 Quart Pressure Pot with Silver Gun and Hose

If you’re tackling large surface areas like buses, trucks, or vans, the Astro 2PG8S 2 Quart Pressure Pot with Silver Gun and Hose offers a compact yet powerful solution. Its 2-quart capacity lets you mix and spray enough material per load without frequent refills. The included pressure gauge and fluid regulator guarantee precise control, while the 1.7mm nozzle covers big areas efficiently. The 6-foot twin hose provides flexibility, making movement easy during application. Overall, this system is perfect for professionals needing consistent, smooth finishes on large surfaces, combining portability with reliable performance. It’s an excellent choice for efficient, high-quality spraying.

Best For: professional painters and contractors working on large surfaces like buses, trucks, and vans who need efficient, portable spraying equipment.

Pros:

- Compact 2-quart capacity allows for quick, efficient spraying with minimal refills

- Includes pressure gauge and fluid regulator for precise control

- 6-foot twin hose provides excellent mobility and ease of use

Cons:

- 1.7mm nozzle may not be suitable for fine detail work

- Limited capacity may require multiple refills for very large projects

- May be less suitable for small or intricate applications due to its size and design

Presto 01362 6-Quart Stainless Steel Pressure Cooker

For anyone seeking a reliable pressure cooker that combines efficiency with safety, the Presto 01362 6-Quart Stainless Steel Pressure Cooker stands out. It cooks chicken, fish, meat, and vegetables quickly while tenderizing tougher cuts. Made from durable stainless steel, it’s compatible with regular, smooth-top, and induction ranges. Safety features include a pressure regulator that maintains proper pressure automatically and a cover lock indicator that signals when pressure exists, preventing accidental opening. The helper handle makes handling easier, and the dishwasher-safe design simplifies cleanup. Plus, it comes with a 64-page instruction and recipe book, ensuring safe, efficient cooking every time.

Best For: Home cooks seeking a durable, safe, and efficient pressure cooker to prepare a variety of meals quickly and easily.

Pros:

- Made from durable stainless steel compatible with various cooktops, including induction

- Safety features like automatic pressure regulation and cover lock indicator for secure operation

- Dishwasher safe for easy cleaning, with included recipe and instruction book

Cons:

- Sealing ring and overpressure plug require hand washing, adding extra cleaning steps

- 6-quart capacity may be limiting for larger families or batch cooking

- Longer warranty coverage (12 years) might not appeal to those preferring shorter-term guarantees

Clamp On Pressure Cooker, 26 Quart Aluminum Pressure Cooker

The Clamp On Pressure Cooker, 26 Quart Aluminum, stands out as an excellent choice for busy families or commercial kitchens that need rapid, reliable meal preparation. It can break through the standard 212°F boiling point to reach 233°F, cooking food about 70% faster and saving time and energy. Its safety features are impressive, including quadruple safety devices like pressure regulators, a safety valve, and a strengthened clamp-on bar for secure lid locking. Made from durable aluminum, it offers a large 26-quart capacity, perfect for large meals. Its simple rotation mechanism makes opening and closing quick and safe, making it a versatile, efficient kitchen tool.

Best For: families and commercial kitchens needing fast, efficient, and safe high-capacity pressure cooking.

Pros:

- Cooks food approximately 70% faster than traditional methods, saving time and energy.

- Equipped with quadruple safety devices, including pressure regulators and a safety valve, ensuring maximum safety.

- Durable aluminum construction with a large 26-quart capacity ideal for large meals or commercial use.

Cons:

- Heavy and bulky, which may make handling and storage challenging.

- Requires understanding of safety mechanisms and operation, potentially needing a learning curve for new users.

- Aluminum construction may be less durable over time compared to stainless steel in high-use environments.

Barton 22-Quart Pressure Canner

The Barton 22-Quart Pressure Canner stands out as an excellent choice for home cooks who prioritize safety and precise pressure control. Made from heavy gauge, rustproof polished aluminum, it’s versatile enough for gas, electric, induction, or ceramic stoves. The deluxe pressure dial gauge ensures accurate readings, vital for safe, high-quality canning at various altitudes. Its spring safety device and sure-locking lid system prevent accidents and accidental opening under pressure. With included racks, it maximizes space and prevents food from sticking. Overall, this canner offers durability, easy cleaning, and reliable performance for those seeking flawless canning results.

Best For: home cooks seeking a versatile, safe, and reliable pressure canner for preserving a wide variety of foods at different altitudes.

Pros:

- Made from durable, rustproof polished aluminum suitable for various stove types.

- Features a precise pressure dial gauge and safety mechanisms for secure, high-altitude canning.

- Includes racks to optimize space and prevent food from sticking, enhancing usability.

Cons:

- May be heavier and bulkier than smaller canning options, requiring ample storage space.

- Requires careful monitoring of pressure and temperature for optimal safety.

- The 22-quart capacity might be too large for small batch canning needs or limited kitchen space.

12 Qt Stainless steel Electric Pressure Canner

A 12-quart stainless steel electric pressure canner stands out as an ideal choice for home cooks who prioritize versatility and safety. Its spacious 12-quart capacity allows me to process large batches efficiently, saving time. The dual canning functions—pressure canning for low-acid foods and water bath canning for fruits and jams—make it highly adaptable. I appreciate the easy-to-use digital interface, LED icons, and simple controls that guide me through each step automatically. With advanced safety features like cover-locking and temperature sensors, I feel confident that my canning is secure and reliable. This automated, user-friendly design truly simplifies home preservation.

Best For: Home cooks seeking a versatile, safe, and easy-to-use electric pressure canner capable of handling large batches of low-acid and high-acid foods.

Pros:

- Combines pressure canning and water bath canning to accommodate a variety of foods.

- User-friendly digital interface with LED icons and automated guidance simplifies the process.

- Equipped with ten safety features, including cover-locking and temperature sensors, ensuring secure operation.

Cons:

- Larger size may require substantial storage space in the kitchen.

- As an electric appliance, it may have a higher energy consumption compared to stovetop canners.

- Limited to the 12-quart capacity, which might not be suitable for very small batch canning needs.

Fuji Spray Mini-Mite 5 Platinum T70 HVLP Spray System

For those seeking a versatile and powerful spray system, the Fuji Spray Mini-Mite 5 Platinum T70 HVLP stands out with its 5-stage turbine that delivers 9.5 PSI, making it ideal for spraying thicker coatings quickly and efficiently. It features a large 2-quart pressure pot with doubles bottom feed capacity, so you can work longer without refilling. Noise reduction covers keep operation quieter, and the Heat Dissipation Chamber maintains cool, consistent performance. The side pattern control knob allows precise fan adjustments, and it can spray at any angle, including upside down. Compact and user-friendly, this system is perfect for both professional and DIY projects.

Best For: DIY enthusiasts and professionals seeking a high-power, versatile spray system capable of handling thick coatings and extended projects with ease.

Pros:

- Powerful 5-stage turbine delivers 9.5 PSI for efficient spraying of thick coatings

- Large 2-quart pressure pot with double bottom feed for prolonged use without frequent refills

- Noise reduction covers and Heat Dissipation Chamber ensure quieter operation and consistent performance

Cons:

- May be heavier and less portable compared to smaller, handheld sprayers

- Setup and cleaning can be time-consuming for beginners unfamiliar with HVLP systems

- Higher initial cost may be a consideration for casual users

Factors to Consider When Choosing a Pressure Pot System for Fine Finish

When selecting a pressure pot system for a fine finish, I consider several key factors to guarantee the best results. Things like material compatibility, pressure control accuracy, and spray gun quality directly impact the quality of the finish. Additionally, I look at capacity and ease of cleaning to match my project needs and workflow.

Material Compatibility

Selecting a pressure pot system that’s compatible with your coatings is essential to achieving a flawless finish. You need to confirm the system works well with the specific materials you plan to use, whether automotive paints, latex, varnishes, or adhesives. Check that the tank and hoses are resistant to chemical corrosion from solvents, acids, or reactive substances in your coatings. It’s also important to verify that the spray gun nozzle sizes and flow rates match the viscosity of your materials to prevent clogging or uneven coverage. Additionally, verify that the system supports the required pressure range, typically between 30-45 psi, for a fine, consistent application. Finally, consider the construction materials, like stainless steel or coated steel, to ensure durability in your specific working environment.

Pressure Regulation Precision

Achieving a flawless finish hinges on precise pressure regulation, as even small fluctuations can cause uneven coatings or defects. It’s essential to choose a system with reliable gauges and adjustable regulators, allowing me to fine-tune pressure during application. Maintaining a stable pressure within the recommended range, usually between 30-45 psi, is critical for a smooth, professional surface. Variations in pressure can lead to texture inconsistencies, drips, or uneven coverage, which ruin the finish. Advanced features like automatic pressure control or digital readouts help me monitor and adjust pressure accurately, ensuring consistent results every time. When selecting a pressure pot system, I prioritize those with precise regulation capabilities that support reliable, repeatable finishes — key for achieving the high-quality look I seek.

Spray Gun Quality

The quality of your spray gun plays a crucial role in delivering a flawless finish, so it’s important to pay attention to its design and features. High-quality spray guns have precision-machined fluid nozzles, typically between 1.3mm and 1.5mm tips, which produce smooth, consistent spray patterns essential for fine finishes. Durability is also key—look for guns made from corrosion-resistant materials like stainless steel or hardened aluminum to ensure longevity and reliable performance over time. Adjustable air and fluid flow controls allow you to fine-tune the spray pattern and material application, giving you better control. Additionally, a well-designed gun offers even fan width and atomization, reducing overspray and orange peel effects. Ergonomic features, such as comfortable grips and balanced weight, help maintain control during extended use.

Capacity Needs

Choosing the right pressure pot capacity depends on the volume of material you need to spray or cast. I recommend evaluating your typical project size to select a tank that minimizes refilling and maximizes efficiency. For large jobs like automotive painting or casting, a bigger tank, such as a 10-liter or 22-quart system, is ideal, as it handles higher throughput without interruption. For finer or smaller tasks, like detailed finishes or craft projects, smaller tanks—like 2-quart or 5-gallon options—are more manageable and easier to handle. Also, consider your maximum material flow per session to ensure the pressure pot can sustain continuous operation. Matching the tank size to your project scale avoids waste and keeps your workflow smooth and efficient.

Ease of Cleaning

When selecting a pressure pot system for fine finishes, ease of cleaning plays a crucial role in maintaining consistent performance. Systems with smooth, corrosion-resistant internal surfaces make cleaning straightforward, preventing paint buildup that can affect spray quality. Removable and washable components like lids, gaskets, and spray guns simplify maintenance and save time. Quick-release fittings and clamps allow for quick disassembly, making thorough cleaning less labor-intensive. Choosing pressure pots with minimal crevices and seamless welds reduces areas where paint can accumulate, ensuring more effective cleaning. Regularly flushing the system with suitable solvents or water is essential to prevent clogs and maintain ideal spray performance. Prioritizing ease of cleaning helps ensure consistent, flawless finishes and reduces downtime in your workflow.

Durability and Build

Durability and build quality are essential factors to contemplate because they directly influence a pressure pot system’s longevity and performance. I recommend systems made from heavy-duty steel or aluminum, as these materials resist corrosion and stand up to frequent use. Reinforced lids with gaskets or metal-to-metal seals ensure secure closures that won’t leak or warp under high pressure. The pressure vessel should have thick walls and high-quality welds to handle consistent operating pressures without cracking. Components like pressure gauges, regulators, and fittings must be crafted from durable materials such as brass or stainless steel for reliable performance over time. Additionally, proper sealing mechanisms and anti-rust finishes help maintain the system’s integrity, even after exposure to coatings, solvents, or cleaning agents.

Safety Features

Safety features are essential to guarantee that pressure pot systems operate securely during fine finish applications. I always look for systems with safety valves that automatically release excess pressure, preventing over-pressurization. A reliable pressure gauge is necessary to monitor pressure levels and keep them within safe limits, reducing risks. Locking lids and secure sealing mechanisms help prevent accidental lid release and leaks under high pressure, ensuring safety during operation. Features like pressure relief valves and automatic shut-offs provide an extra layer of protection, minimizing hazards for users. Proper construction using durable, high-quality materials also plays a crucial role in safety, as it reduces the risk of rupture or failure during demanding tasks. Prioritizing these safety features ensures a safer working environment and flawless finishes.

Cost and Budget

Choosing the right pressure pot system depends heavily on your budget, as prices can vary widely from affordable DIY models around $50 to professional-grade equipment exceeding $500. Lower-cost systems might limit capacity and features, which could affect the quality of your finish. On the other hand, investing in a higher-priced system often means better build quality, more precise pressure controls, and increased durability—saving you money in the long run. It’s vital to contemplate long-term costs like maintenance, replacement parts, and upgrades. Staying within your budget allows you to also allocate funds for accessories such as hoses, spray guns, or fittings. Balancing cost with quality ensures you get a system that meets your needs without overspending, ultimately helping you achieve a flawless fine finish efficiently.

Frequently Asked Questions

How Does Pressure Consistency Affect the Quality of a Fine Finish?

Pressure consistency is vital for achieving a fine finish because it ensures a steady flow of material, preventing uneven textures or blemishes. When pressure remains stable, I notice smoother, more uniform results, reducing the need for touch-ups. Inconsistent pressure can cause variations that ruin the surface quality. So, I always prioritize systems that deliver reliable pressure, helping me attain that flawless, professional look I aim for.

What Safety Features Are Essential in High-Pressure Pot Systems?

When selecting high-pressure pot systems, I always prioritize safety features like pressure relief valves, which prevent over-pressurization, and sturdy lock mechanisms to avoid accidental releases. I also look for burst discs and clear gauges for real-time monitoring. These features give me peace of mind, ensuring safe operation while maintaining the high standards needed for a flawless, fine finish. Safety isn’t just an option; it’s essential.

Can These Systems Be Used for Both Painting and Casting?

Yes, these systems can be used for both painting and casting. I’ve found that with the right adjustments, like pressure settings and nozzle sizes, I can switch between tasks seamlessly. Just make sure to clean the system thoroughly between uses to avoid contamination. Using a pressure pot system for both applications saves me time and money, and I get consistent, professional results every time.

How Maintenance-Intensive Are These Pressure Pot Systems Over Time?

Think of these pressure pot systems as a well-tuned engine—they require regular maintenance to keep running smoothly. Over time, I find that cleaning the filters, inspecting hoses, and checking seals are essential to prevent downtime. While not overly demanding, neglect can lead to issues like inconsistent finishes. With routine care, these systems stay reliable, ensuring your projects always come out flawless and professional.

Are There Specific Accessories Recommended for Achieving a Flawless Finish?

Absolutely, I recommend using fine mesh filters and high-quality hoses to achieve a flawless finish. A pressure regulator ensures consistent pressure, which is vital for even coating. Additionally, adding a quick-release valve makes cleanup easier. I’ve found that investing in these accessories helps maintain a smooth, professional result, reduces overspray, and keeps your system running efficiently. Don’t overlook regular cleaning; it’s key to flawless, lasting finishes.

Conclusion

Choosing the right pressure pot system is like finding the perfect brush—it makes all the difference in achieving a flawless finish. Whether you’re casting, painting, or canning, the options I’ve shared can turn your projects into masterpieces. Remember, it’s not just about tools but how you wield them. So, pick wisely, and let your craftsmanship shine brighter than ever—because in this world, detail is the artist’s best friend.